One Project – Big Impact

Measuring the Environmental and Economic Impact of the JI Case Tractor Factory Deconstruction Project

Urban Evolutions deconstructed the former J.I. Case Plow Works factory, which was built in 1901, in Racine, Wisconsin.

By salvaging what ended up being over 2 million board feet of lumber, 5,000 tons of CO2 was prevented from being released into the atmosphere. That’s the equivalent of keeping over 1000 cars off the road for a year!

The deconstruction of the factory further led to the creation of 28 jobs for up to nine months.

Compare that to a few guys and a wrecking ball and you see the kind of impact deconstruction can have.

As compared to demolition, there are many benefits to the deconstruction of buildings, factories and homes:

- keeping carbon from being released into the atmosphere (a process known as carbon sequestration)

- job creation

- diverting building waste from landfills

- reusing lumber resources.

Let’s dive in!

Urban Evolutions reintegrated heart pine timbers and factory maple into retail stores, hospitality projects and residences throughout the United States. Click here to read where you can see this historic material now!

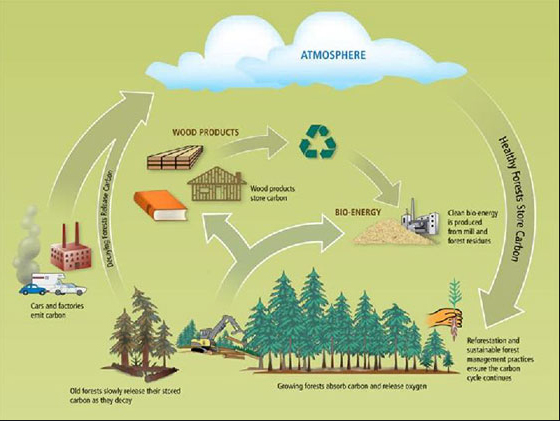

CARBON SEQUESTRATION

Many of you know about carbon sequestration. In the case of salvaged wood, it is the natural process by which carbon dioxide is removed from the atmosphere and held in solid form.

The capture or sequestration of carbon dioxide from the atmosphere slows or may reverse atmospheric CO2 pollution, mitigating or potentially reversing global warming.

Carbon sequestration, when it comes to wood, simply means salvaging and maintaining lumber in lumber form, rather than letting it burn or decompose in a landfill or as mulch.

DIVERTING WASTE FROM LANDFILLS

Every year, the US buries 33 million tons of wood-related construction and demolition debris in landfills, releasing 5 million tons of methane gas. Methane, by the way, releases 20 times more carbon than CO2 alone.

Overall, wood accounts for around 10% of ALL material deposited in landfills annually. (source)

Wood recycling rates are a dismal 31%. If you subtract the wood that is burned and mulched rather than reused, it drops to just 8%. As a comparison, concrete and structural steel recycling rates are over 82%.

REUSING LUMBER RESOURCES

Deconstruction promotes reusing valuable lumber resources instead of cutting new growth timber. For every timber that is re-used in a home or commercial building, that is one less tree that is cut down from our forests.

Less pressure on our forests allows us to plant more than we harvest and allows virgin trees to grow to full maturity before being harvested.

Currently our forests are still only 66% of the land size they were in the 1850s. (source)

When we counted the growth rings on the old growth timbers from the JI Case Factory, we found the trees were 400-500 years old.

While that is an exception, more than a rule, many buildings built before the 1940s, were built with old growth or slow growing lumber.

Deconstruction is a responsible alternative to traditional demolition. If there is adequate time, deconstruction teams can recycle and repurpose 50-90% of the entire building. The deconstruction and reclamation process has a tremendous positive impact on the environment, job creation and our nations forests.

Contact Us